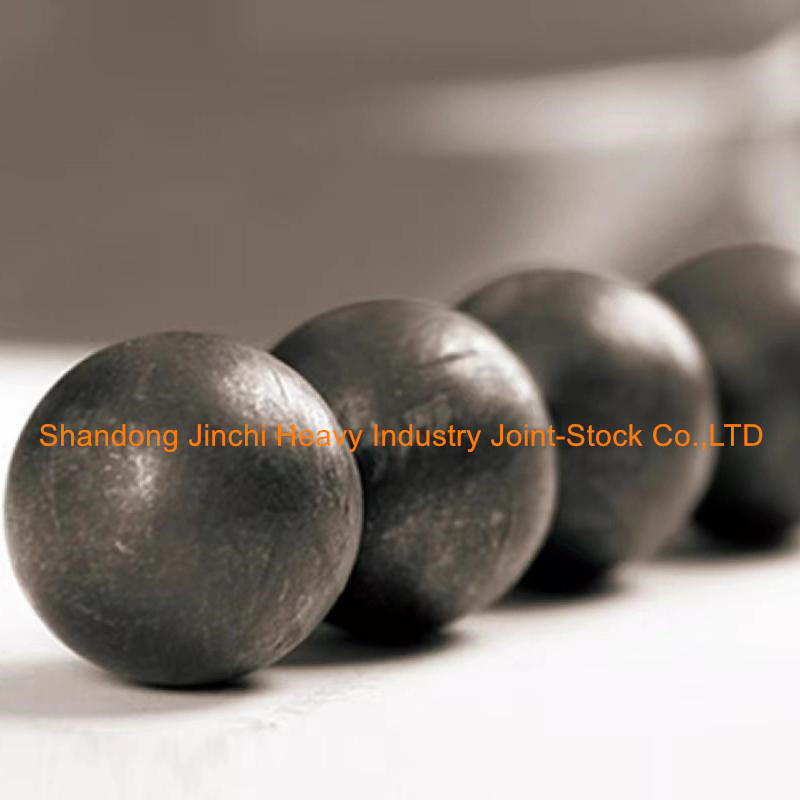

Forged and casting grinding media balls

Forged and casting grinding media balls

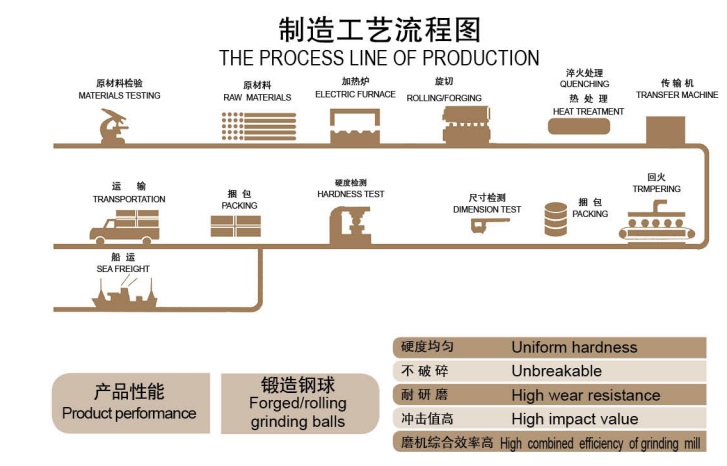

Uniform Hardness;

High Wear Resistance;

Low Breakage Rate;

Without loss of round;

High impact toughness;

Breakage rate: <1%

Forged and casting grinding media balls

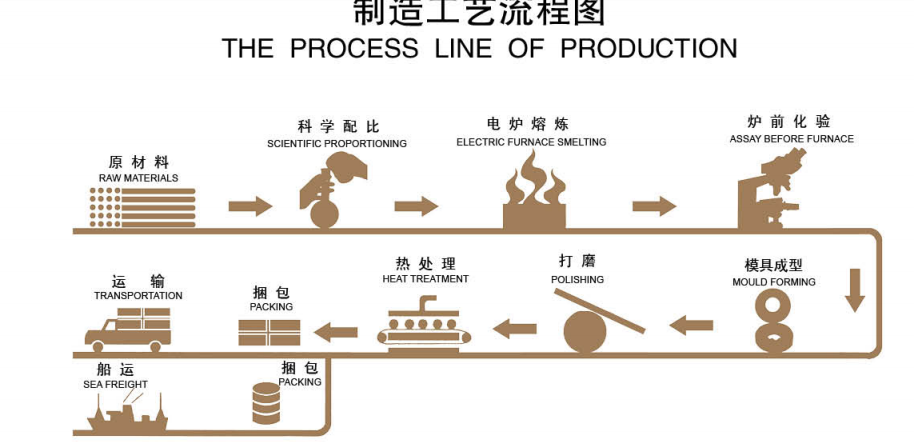

Shandong Jinchi Heavy Industry Joint Stock Co.,Ltd, Is a professional manufacturer of grinding products. The main products of our company are GRINDING FORGED STEEL BALLS, GRINDING CASTING STEEL BALLS,GRINDING RODS, GRINDING CYLPEBS, with specifications all reaching international standards and annual production capacity is over 100,000 tons.

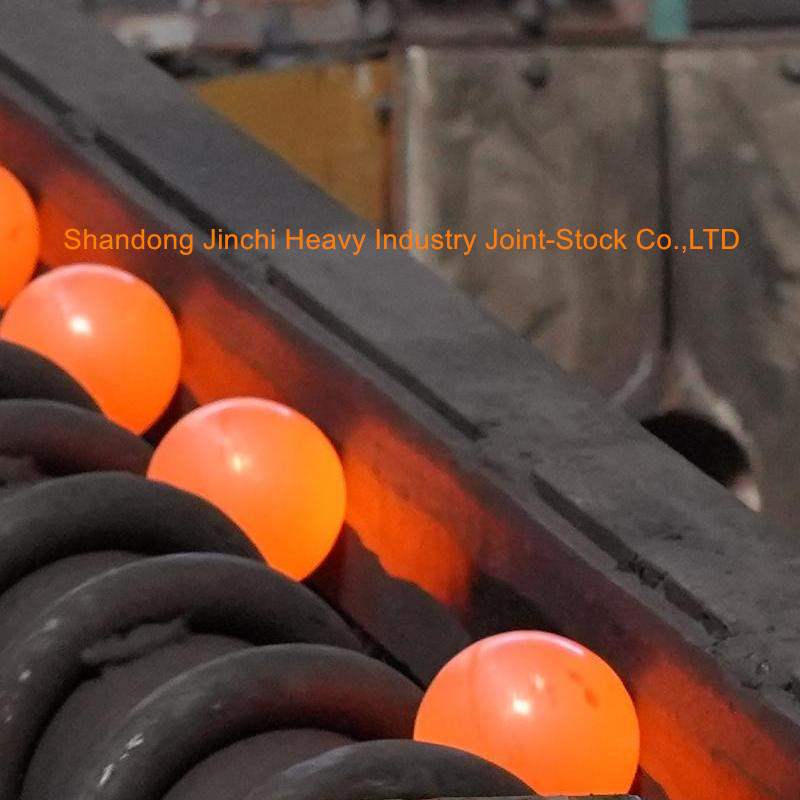

High-quality raw materials, advanced full-automatic production line, unique heat treatment technology and strict quality control system, these four major advantages make sure our products have stable impact performance, high wear resistance and high combined efficiency of grinding mill.

The company has an independent laboratory, the advanced and accurate lab equipment, to ensure that each step of the production process is performed in accordance with the quality standards. Moreover, our company has been accredited with ISO9001 Quality Certification, OHSAS18001 Occupational health and safety certification and ISO14001 environmental management system certification.

Forged ball chemical composition

Materials | C% | Si% | Mn% | P% | S% | Cr% |

B2 | 0.70-0.85 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | 0.4-0.6 |

B2-1 | 0.55-0.70 | 0.15-0.30 | 0.65-0.85 | ≤0.020 | ≤0.020 | 0.70-1.10 |

High Carbon B2 | 0.85-1.10 | 0.15-0.45 | 0.40-1.20 | ≤0.035 | ≤0.035 | 0.20-1.10 |

B3 | 0.58-0.66 | 1.70-1.90 | 0.68-0.80 | ≤0.030 | ≤0.030 | 0.78-0.90 |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.25max |

B4 | 0.65-0.75 | 1.20-1.40 | 0.50-0.70 | ≤0.025 | ≤0.025 | 0.85-1.00 |

B6 | 0.75-0.90 | 0.17-0.37 | 0.8-1.02 | ≤0.035 | ≤0.035 | 0.88-0.98 |

B6-1 | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | ≤0.020 | ≤0.020 | 0.88-0.98 |

BU | 0.95-1.05 | 0.15-0.35 | 0.95-1.05 | ≤0.025 | ≤0.025 | 0.45-0.55 |

1090 | 0.90-1.10 | 0.17-0.37 | 0.60-0.90 | ≤0.025 | ≤0.025 | ≤0.025 |

42CrMo | 0.38-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 |

40Cr | 0.37-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.80-1.10 |

65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 |

60MN | 0.57-0.65 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

50MN | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

Specification of Grinding Ball:

Diameter(mm) | Diameter Tolerance(mm) | Surface Hardness(HRC) | Impact Toughness(j/cm2) |

Φ20 | +2, —1 | >60HRC | ≥12 |

Φ25 | |||

Φ30 | |||

Φ40 | |||

Φ50 | |||

Φ60 | +3, —2 | ||

Φ70 | |||

Φ80 | |||

Φ90 | |||

Φ100 | +4, —2 | ||

Φ110 | |||

Φ120 | >58HRC | ||

Φ130 | |||

Φ140 | +4, —3 | >55HRC | |

Φ150 |

Casting grinding ball Chemical composition

Chemical Components | ||||||||

Type | Chemical components | |||||||

C | Si | Mn | Cr | Mo | Cu | P | S | |

Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

Medium-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

High-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |