Low Breakage Rate Grinding Steel Ball

Low Breakage Rate Grinding Steel Ball

Product Features:

1. Uniform hardness

2. High grinding resistance

3. High impact value

4. Low breakage: less than 1%

Low Breakage Rate Grinding Steel Ball

Shandong Jinchi Heavy Industry Joint-stock Co.,LTD produce Low Breakage Rate Grinding Steel Ball for over 20 years and supply different mining companies like gold mine, copper mine, zinc mine, iron mine from Ghana, Mexico, Canada, South africa, Chile, Peru, Congo, Zambia and so on.

We produce Low Breakage Rate Grinding Steel Ball with very strict quality control system. An independent laboratory, the advanced and accurate lab equipment, to ensure that each step of the production process is performed in accordance with the quality standards.our company have also been verified with ISO9001 Quality Certification, ISO45001 Occupational health and safety certification and ISO14001 environmental management system certification.

Chemical Composition of Low Breakage Rate Grinding Steel Ball

Materials | C% | Si% | Mn% | P% | S% | Cr% |

B2 | 0.70-0.85 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | 0.4-0.6 |

B2-1 | 0.55-0.70 | 0.15-0.30 | 0.65-0.85 | ≤0.020 | ≤0.020 | 0.70-1.10 |

High Carbon B2 | 0.85-1.10 | 0.15-0.45 | 0.40-1.20 | ≤0.035 | ≤0.035 | 0.20-1.10 |

B3 | 0.58-0.66 | 1.70-1.90 | 0.68-0.80 | ≤0.030 | ≤0.030 | 0.78-0.90 |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.25max |

B4 | 0.65-0.75 | 1.20-1.40 | 0.50-0.70 | ≤0.025 | ≤0.025 | 0.85-1.00 |

B6 | 0.75-0.90 | 0.17-0.37 | 0.8-1.02 | ≤0.035 | ≤0.035 | 0.88-0.98 |

B6-1 | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | ≤0.020 | ≤0.020 | 0.88-0.98 |

42CrMo | 0.38-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 |

40Cr | 0.37-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.80-1.10 |

65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 |

60MN | 0.57-0.65 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

50MN | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

Specification of Low Breakage Rate Grinding Steel Ball

Diameter(mm) | Diameter Tolerance(mm) | Surface Hardness(HRC) | Impact Toughness(j/cm2) |

Φ20 | +2, —1 | >60HRC | ≥12 |

Φ25 | |||

Φ30 | |||

Φ40 | |||

Φ50 | |||

Φ60 | +3, —2 | ||

Φ70 | |||

Φ80 | |||

Φ90 | |||

Φ100 | +4, —2 | ||

Φ110 | |||

Φ120 | >58HRC | ||

Φ130 | |||

Φ140 | +4, —3 | >55HRC | |

Φ150 |

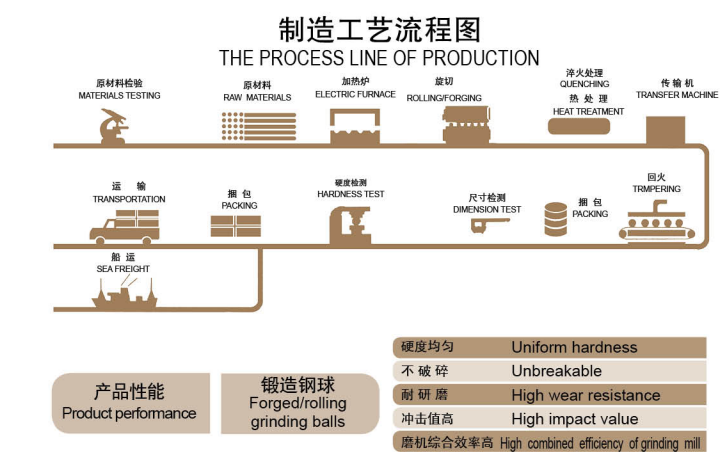

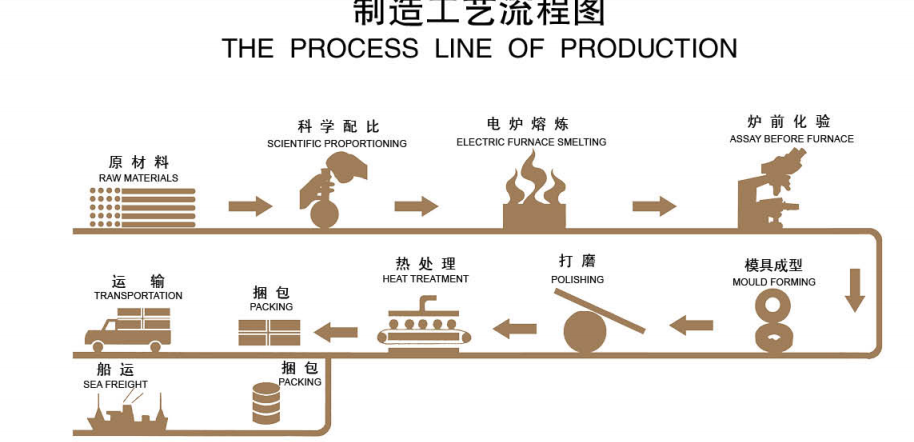

Explanation of quality control

Shandong Jinchi Heavy Industry Joint-Stock Co., Ltd. strictly controls each link of wear-resistant steel ball from steel plant selection, raw material purchase, steel inspection, quenching and tempering process control, finished product inspection, and strictly controls the performance index of steel ball according to the ISO9001:2015 quality management system certification procedure of the company, so as to ensure that the performance index of steel ball meets the technical requirements of the project and industry related requirements Technical specifications. Ensure the wear resistance, stability, maturity and reliability of steel ball.

Guarantee measures for raw material ordering

Our company has strategic cooperation agreements with well-known domestic state-owned enterprises, such as Laiwu branch of Shandong Iron and Steel Co., Ltd., Chengde Jianlong Special Steel Co., Ltd. and Huaigang Special Steel Co., Ltd. of Jiangsu shagang group. Each stage from material ordering to material inspection is reviewed and approved by technical experts, and finally determined by the technical director after being signed and confirmed by the relevant responsible person.

Production equipment performance assurance measures

All of them are produced with the most advanced and professional equipment, and cooperate with the process and quality inspection personnel to make the original records of various parameters in the production process, and operate and produce in strict accordance with the process requirements and specifications.

Process technology and quality inspection performance guarantee

Set up the project process specialist and quality inspector, set up the process in strict accordance with the parameters and indicators required by the contract and supervise the implementation of the process. The quality inspector shall track and record each parameter in the whole process.

Packaging and transportation performance guarantee

The packaging standard of the product is strictly in accordance with the international standards, to ensure that it can meet the lifting requirements for many times. Our company has established a strategic partnership system with several key shipping companies and logistics companies at home and abroad. We have transportation insurance for each vehicle, which greatly enhances our ability to resist risks.

We can supply Low Breakage Rate Grinding Steel Ball

Chemical Components | ||||||||

Type | Chemical components | |||||||

C | Si | Mn | Cr | Mo | Cu | P | S | |

Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

Medium-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

High-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |

Product Features:

1. uniform hardness

2. high grinding resistance

3. high impact value

4. low breakage: less than 1%

We provide value for our clients thru our qualified grinding ball, grinding media products, professional service and reliable delivery.

Shandong jinchi heavy enterprise joint-stock co.,ltd is looking ahead to cooperating with you to create a better future!