Hot Forging Steel Ball

Hot Forging Steel Ball have unique size, round geometry, excessive hardness and desirable mechanical houses, and have high-quality great of wear and tear resistance, no deformation and no cracking. its characteristics are as follows:

1. high typical hardness: the floor hardness can attain fifty eight-65hrc, the extent hardness can reach 55-62hrc, and the hardness gradient distribution is uniform;

2. excessive effect toughness: the impact toughness is more than 12j / cm2;

3. low crushing charge: the anti stripping and anti crushing performance is more than 10 instances that of everyday solid and forged metal balls, the impact times of falling balls are more than 20000, and the real crushing rate isn't greater than 1%, that's close to no crushing.

Shandong jinchi heavy company co., ltd. is a modern-day-day manufacturing business enterprise integrating r & d, manufacturing and sales! Hot Forging Steel Ball of the employer are put on-resistant metal balls, placed on-resistant steel rods, put on-resistant steel forgings, mill lining plates, metal systems, and mine accessories. great creates emblem and excellent creates blessings; advanced manipulate concepts, state-of-the-art procedure machine, and notable workforce have implemented an appropriate first rate appeal in every link of the production way, and realized the whole upgrading of product excellent.

Hot Forging Steel Ball merchandise are broadly utilized in various black and non-ferrous metallic mines, mineral processing flowers, thermal power vegetation, cement vegetation, refractory flora and other industries, and are well obtained via customers at domestic and abroad.

Product Characteristics of Hot Forging Steel Ball

1. Size: 20-75mm

2. Surface hardness: 60-65hrc center hardness: 57-60hrc or above (different specifications and hardness).

3. Product performance:

Uniform hardness

Non crushing and grinding resistance

High impact value

High comprehensive efficiency of the mill

4. Production process

Chemical elements of Hot Forging Steel Ball

Brand | Materials | C | Mn | Si | Cr | S | P | V | |||

JCR-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-3 | 65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.20-0.60 | ≤0.030 | ≤0.030 | ||||

JCR-5 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 | |||

Specification of hot rolling steel Grinding balls | |||||||||||

Nominal diameter | Diameteical | Weight of single ball in average | Surface hardness | Impact toughness | |||||||

Tolerance | |||||||||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | |||||||

Φ20 | +2 -1 | 32 | 60-65 | ≥12 | |||||||

Φ25 | 64 | ||||||||||

Φ30 | 110 | ||||||||||

Φ40 | 263 | ||||||||||

Φ50 | 513 | ||||||||||

Φ60 | +3 -2 | 888 | |||||||||

Φ70 | 1410 | ||||||||||

Φ80 | 2104 | ||||||||||

Φ90 | 2996 | ||||||||||

Φ100 | 4110 | ||||||||||

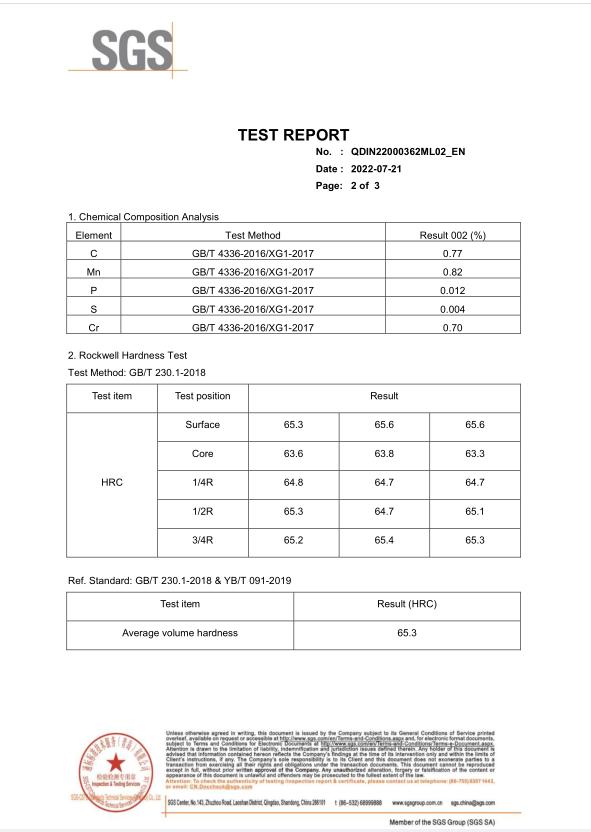

Test Report of Hot Forging Steel Ball

Brand | Materials | C | Mn | Si | Cr | S | P | V | |||

JCR-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-3 | 65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | ||||

JCR-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.20-0.60 | ≤0.030 | ≤0.030 | ||||

JCR-5 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 | |||

Specification of hot rolling steel Grinding balls | |||||||||||

Nominal diameter | Diameteical | Weight of single ball in average | Surface hardness | Impact toughness | |||||||

Tolerance | |||||||||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | |||||||

Φ20 | +2 -1 | 32 | 60-65 | ≥12 | |||||||

Φ25 | 64 | ||||||||||

Φ30 | 110 | ||||||||||

Φ40 | 263 | ||||||||||

Φ50 | 513 | ||||||||||

Φ60 | +3 -2 | 888 | |||||||||

Φ70 | 1410 | ||||||||||

Φ80 | 2104 | ||||||||||

Φ90 | 2996 | ||||||||||

Φ100 | 4110 | ||||||||||