Balls of Steel Cast

Balls of Steel Cast is made through introducing a fluid soften into a mold this is allowed to cool within the form of a sphere. 4 essential elements are required inside the casting manner: the pattern, the mold, the middle, and the partial pattern, from which the authentic template is ready, created within the corresponding cavity of the casting fabric. the center is used to make the pipe or hole inside the very last die, and this component is the final output of the technique. casting can be used to form hot, liquid metals. the abrasive medium is heat dealt with to attain the specified aggregate of hardness, toughness and microstructure to make sure an notable aggregate of damage resistance and toughness.

Shandong jinchi heavy industry co., ltd. is a modern production employer integrating r & d, manufacturing and income! the main products of the company are Balls of Steel Cast, wear-resistant metal rods, put on-resistant steel forgings, mill lining plates, steel systems, and mine accessories. brilliant creates brand and first-rate creates blessings; advanced manipulate standards, sophisticated machine gadget, and remarkable personnel have carried out the proper incredible enchantment in each hyperlink of the manufacturing process, and discovered out the complete upgrading of product first-class.

Balls of Steel Cast parameters

Nominal diameter | Weight of single ball in average | Quantity/ MT | Surface hardness | Endurance impact test |

Φ15 | 13.8 | 72549 | >60 | >10000 |

Φ17 | 20.1 | 49838 | >10000 | |

Φ20 | 32.7 | 30607 | >10000 | |

Φ25 | 64 | 15671 | >10000 | |

Φ30 | 110 | 9069 | >10000 | |

Φ40 | 261 | 3826 | >10000 | |

Φ50 | 510 | 1959 | >10000 | |

Φ60 | 882 | 1134 | >10000 | |

Φ70 | 1401 | 714 | >10000 | |

Φ80 | 2091 | 478 | >58 | >10000 |

Φ90 | 2977 | 336 | >10000 | |

Φ100 | 4084 | 245 | >8000 | |

Φ120 | 7057 | 142 | >8000 | |

Φ130 | 8740 | 115 | >8000 |

Cast Steel Ball quality index

High Chromium Cast Steel Ball quality indicators:

Chromium content ≥10.0%, carbon content between 1.80%-3.20% are called high chromium ball, the national standard requirements of high chromium ball hardness (HRC) must be more than 58, impact value AK ≥3.0J/ 2, if the hardness of high chromium ball must use high temperature quenching + tempering treatment (at present domestic high chromium ball quenching oil quenching and wind quenching two quenching methods), If the test hardness (HRC) is below 54, the High chromium cast steel ball has not been quenched.

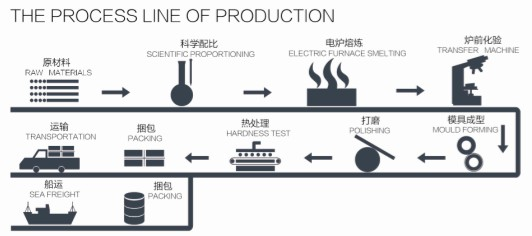

Manufacturing process flow chart

| Nominal diameter (mm) | Weight of single ball in average (g) | Quantity/ MT | Surface hardness (HRC) | Endurance impact test (Times) |

| Φ15 | 13.8 | 72549 | >60 | >10000 |

| Φ17 | 20.1 | 49838 | >10000 | |

| Φ20 | 32.7 | 30607 | >10000 | |

| Φ25 | 64 | 15671 | >10000 | |

| Φ30 | 110 | 9069 | >10000 | |

| Φ40 | 261 | 3826 | >10000 | |

| Φ50 | 510 | 1959 | >10000 | |

| Φ60 | 882 | 1134 | >10000 | |

| Φ70 | 1401 | 714 | >10000 | |

| Φ80 | 2091 | 478 | >58 | >10000 |

| Φ90 | 2977 | 336 | >10000 | |

| Φ100 | 4084 | 245 | >8000 | |

| Φ120 | 7057 | 142 | >8000 | |

| Φ130 | 8740 | 115 | >8000 |