Forged Steel Ball

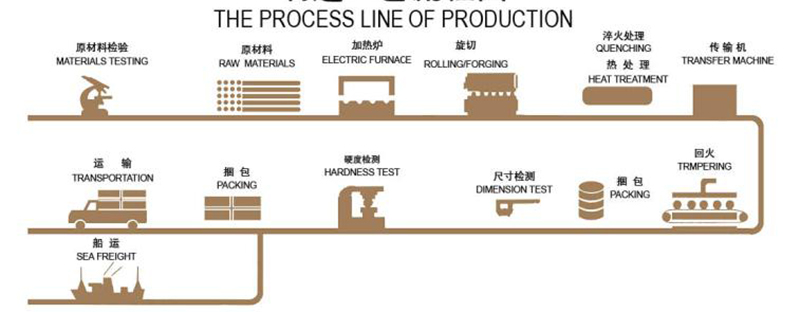

Raw materials: Forged Steel Ball, the raw material required for forging steel balls, is all ordered from large national steel plants, and special processing can be carried out according to the special requirements of different wear-resistant steel ball materials.

Raw material heating: we use energy-saving induction rod heating electric furnace for heating, which can ensure the uniform temperature of the whole raw material and greatly reduce the loss of raw materials. The uniform temperature of raw materials after heating can ensure the uniform hardness of wear-resistant steel balls during heat treatment.

Shandong Jinchi Heavy Industry Co., Ltd. is an export organisation that produces and sells abrasive resistant metal balls. its stable product high-quality is exported to south korea, japan, south africa, the usa, ghana and other nations and areas all of the year round, and is generally praised via clients.

Specification

Brand | Materials | C % | Si % | Mn% | P% | S % | Cr % | Ni% | Cu % | Mo % | Al % |

JC-1 | B2 | 0.70-0.85 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | 0.50-0.60 | ≤0.20 | ≤0.20 | / | 0.015-0.050 |

JC-2 | B2-1 | 0.55-0.70 | 0.15-0.30 | 0.65-0.85 | ≤0.020 | ≤0.020 | 0.70-1.10 | ≤0.20 | ≤0.20 | / | 0.015-0.050 |

JC-3 | B3 | 0.58-0.66 | 1.70-1.90 | 0.68-0.80 | ≤0.030 | ≤0.030 | 0.78-0.90 | ≤0.20 | ≤0.20 | / | 0.015-0.050 |

JC-4 | B4 | 0.65-0.75 | 1.20-1.40 | 0.50-0.70 | ≤0.025 | ≤0.025 | 0.85-1.00 | / | ≤0.25 | / | / |

JC-5 | B6 | 0.75-0.90 | 0.17-0.37 | 0.8-1.02 | ≤0.035 | ≤0.035 | 0.88-0.98 | ≤0.25 | ≤0.25 | 0.06-0.13 | 0.020-0.047 |

JC-6 | B6-1 | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | ≤0.020 | ≤0.020 | 0.88-0.98 | ≤0.25 | ≤0.25 | 0.06-0.13 | 0.020-0.047 |

JC-7 | BU | 0.95-1.05 | 0.15-0.35 | 0.95-1.05 | ≤0.025 | ≤0.025 | 0.45-0.55 | ≤0.06 | ≤0.15 | ≤0.05 | 0.020-0.040 |

JC-8 | 1090 | 0.90-1.10 | 0.17-0.37 | 0.60-0.90 | ≤0.025 | ≤0.025 | ≤0.25 | ≤0.02 | ≤0.02 | / | / |

JC-9 | 42CrMo | 0.38-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 | / | / | 0.15-0.25 | / |

JC-10 | 40Cr | 0.37-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.80-1.10 | / | / | / | / |

JC-11 | 65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 | / | / | / | / |

JC-12 | 60MN | 0.57-0.65 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | / | / |

JC-13 | 50MN | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | / | / |

Application fields

cement building materials, mining metallurgy, power plant coal grinding, chemical industry, machinery and other industries

Production process of forged steel balls

Heat treatment system: through the self-developed water quenching heat treatment production line and scientific heat treatment process, the water inlet temperature and water outlet temperature of the wear-resistant steel ball can be controlled at will, so that the forged wear-resistant ball has higher hardness from the surface to the core, and also has high toughness and extremely low crushing rate. It can maintain the stability of the wear-resistant ball under various harsh working conditions.

Manufacturing process flow chart