Forged Steel Grinding Ball

1. Grade: 45#,50Mn,60Mn,65Mn,B2,B3,BL,BG

2. Diameter: 15mm-150mm

3. Hardness: HRC 55-65

4. Breakage Rate:<1%

5. Impact Value: >12j/Cm^2

6. Falling ball times: ≥20000s

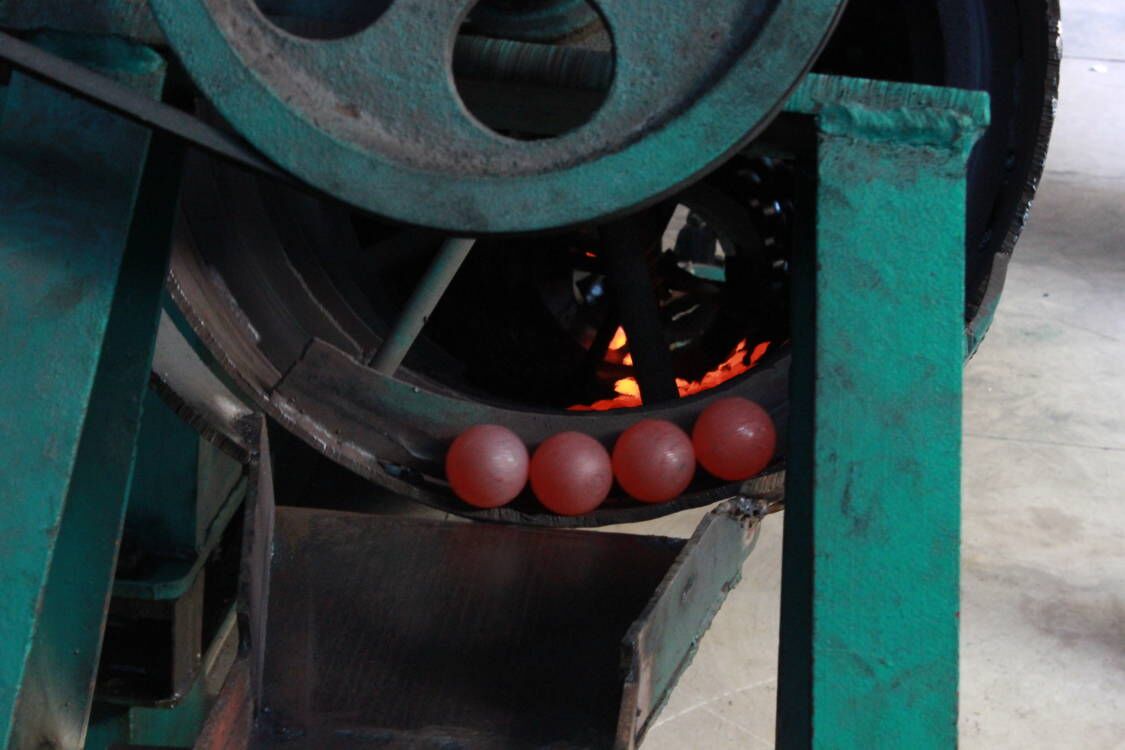

Our forged steel grinding balls are produced by advanced automatic rolling machine ( Balls from 20mm-70mm) + Labor Air Hammer ( 80mm-150mm) with special Heating treatment and strict quality control systerm , which make our Forged grinding balls high wear resistance,unbreakable and high impact value.

Our company has a first-class laboratory, and equipped with advanced testing equipment, such as spectrometer, hardness tester, microscope, drop tester, impact tester, laser cutting machine , etc.,to ensure that our products from raw material into the factory to the production process to the shipment of every link quality control assurance and traceability.

Materials | C% | Si% | Mn% | P% | S% | Cr% |

B2 | 0.70-0.85 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | 0.4-0.6 |

B2-1 | 0.55-0.70 | 0.15-0.30 | 0.65-0.85 | ≤0.020 | ≤0.020 | 0.70-1.10 |

High Carbon B2 | 0.85-1.10 | 0.15-0.45 | 0.40-1.20 | ≤0.035 | ≤0.035 | 0.20-1.10 |

B3 | 0.58-0.66 | 1.70-1.90 | 0.68-0.80 | ≤0.030 | ≤0.030 | 0.78-0.90 |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.25max |

B4 | 0.65-0.75 | 1.20-1.40 | 0.50-0.70 | ≤0.025 | ≤0.025 | 0.85-1.00 |

B6 | 0.75-0.90 | 0.17-0.37 | 0.8-1.02 | ≤0.035 | ≤0.035 | 0.88-0.98 |

B6-1 | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | ≤0.020 | ≤0.020 | 0.88-0.98 |

BU | 0.95-1.05 | 0.15-0.35 | 0.95-1.05 | ≤0.025 | ≤0.025 | 0.45-0.55 |

1090 | 0.90-1.10 | 0.17-0.37 | 0.60-0.90 | ≤0.025 | ≤0.025 | ≤0.025 |

42CrMo | 0.38-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 |

40Cr | 0.37-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.80-1.10 |

65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 |

60MN | 0.57-0.65 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

50MN | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

Guarantee measures for raw material ordering

Our company has strategic cooperation agreements with well-known domestic state-owned enterprises, such as Laiwu branch of Shandong Iron and Steel Co., Ltd., Chengde Jianlong Special Steel Co., Ltd. and Huaigang Special Steel Co., Ltd. of Jiangsu shagang group. Each stage from material ordering to material inspection is reviewed and approved by technical experts, and finally determined by the technical director after being signed and confirmed by the relevant responsible person.

Production equipment performance assurance measures

All of them are produced with the most advanced and professional equipment, and cooperate with the process and quality inspection personnel to make the original records of various parameters in the production process, and operate and produce in strict accordance with the process requirements and specifications.

Application field: mines, cement plants, power station, chemical industries etc.

Packing: Steel drum or Big bag.