Grinding Rolling Balls

Grinding Rolling Balls have precise size, round geometry, high hardness and good mechanical properties, and have excellent quality of wear resistance, no deformation and no cracking. Its characteristics are as follows:

1. High overall hardness: the surface hardness can reach 58-65hrc, the volume hardness can reach 55-62hrc, and the hardness gradient distribution is uniform;

2. High impact toughness: the impact toughness is greater than 12j / cm2;

3. Low crushing rate: the anti stripping and anti crushing performance is more than 10 times that of ordinary cast and forged steel balls, the impact times of falling balls are more than 20000, and the actual crushing rate is not more than 1%, which is close to no crushing.

Grinding Rolling Balls

Shandong Jinchi Heavy Industry Joint Stock Co.,Ltd, Is a professional manufacturer of grinding products. The main products of our company are GRINDING ROLLING STEEL BALLS, GRINDING FORGED STEEL BALLS,CASTING STEEL BALLS,GRINDING RODS, GRINDING CYLPEBS, with specifications all reaching international standards and annual production capacity is over 100,000 tons.

High-quality raw materials, advanced full-automatic production line, unique heat treatment technology and strict quality control system, these four major advantages make sure our products have stable impact performance, high wear resistance and high combined efficiency of grinding mill.

The employer has an unbiased laboratory, the advanced and correct lab system, to ensure that every step of the manufacturing technique is carried out according with the quality requirements. furthermore, our enterprise has been approved with iso9001 nice certification, ohsas18001 occupational fitness and safety certification and iso14001 environmental control gadget certification.

Chemical Composition of Grinding Rolling Balls

Materials | C% | Si% | Mn% | P% | S% | Cr% |

B2 | 0.70-0.85 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | 0.4-0.6 |

B2-1 | 0.55-0.70 | 0.15-0.30 | 0.65-0.85 | ≤0.020 | ≤0.020 | 0.70-1.10 |

High Carbon B2 | 0.85-1.10 | 0.15-0.45 | 0.40-1.20 | ≤0.035 | ≤0.035 | 0.20-1.10 |

B3 | 0.58-0.66 | 1.70-1.90 | 0.68-0.80 | ≤0.030 | ≤0.030 | 0.78-0.90 |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.25max |

B4 | 0.65-0.75 | 1.20-1.40 | 0.50-0.70 | ≤0.025 | ≤0.025 | 0.85-1.00 |

B6 | 0.75-0.90 | 0.17-0.37 | 0.8-1.02 | ≤0.035 | ≤0.035 | 0.88-0.98 |

B6-1 | 0.82-0.90 | 0.15-0.35 | 0.90-1.05 | ≤0.020 | ≤0.020 | 0.88-0.98 |

42CrMo | 0.38-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.90-1.20 |

40Cr | 0.37-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.80-1.10 |

65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 |

60MN | 0.57-0.65 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

50MN | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | ≤0.035 | ≤0.035 | ≤0.25 |

Specification of Grinding Rolling Balls

Diameter(mm) | Diameter Tolerance(mm) | Surface Hardness(HRC) | Impact Toughness(j/cm2) |

Φ20 | +2, —1 | >60HRC | ≥12 |

Φ25 | |||

Φ30 | |||

Φ40 | |||

Φ50 | |||

Φ60 | +3, —2 | ||

Φ70 | |||

Φ80 | |||

Φ90 | |||

Φ100 | +4, —2 | ||

Φ110 | |||

Φ120 | >58HRC | ||

Φ130 | |||

Φ140 | +4, —3 | >55HRC | |

Φ150 |

Product Features of Grinding Rolling Balls

1. Size: 20-75mm

2. Surface hardness: 60-65hrc center hardness: 57-60hrc or above (different specifications and hardness).

3. Product performance:

Uniform hardness

Non crushing and grinding resistance

High impact value

High comprehensive efficiency of the mill

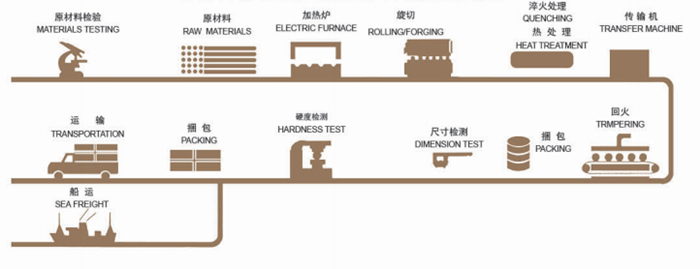

4. Production process

Manufacturing Process

The Process Line of Production

Packing

(1)Container Bag:Dia20mm-150mm 1000kg/Container Bag

(2)Steel Drums:Dia20mm-80mm 900kg/Drum Dia90mm-150mm 850kg/Drums

(3)Steel Drum on Pallet or Bag on Pallet